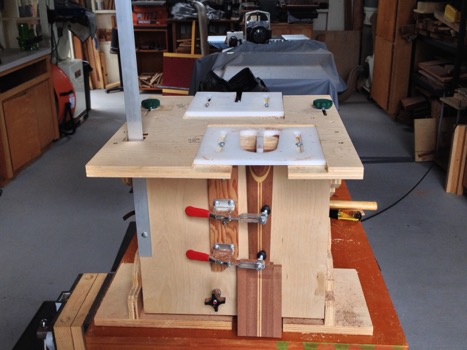

The day I’ve been waiting for has finally arrived. I made a neck mortise and tenon jig awhile back that should, in theory, create a perfectly aligned joint while also compensating for any body front/top errors (e.g., not exactly 90 deg). Of course, the jig also has the potential to quickly turn a lot of work into a member for the wall of shame.

After spending the entire morning doing many test runs on scrap, and confident it’s good, I dialed in the body dimensions using that aluminum bar sticking up in the air. Too confusing to get into details but it’s the slickest part of the jig. Set up the plunge router with a custom depth stop to cut a tenon exactly so the tenon shoulder is at the 14th fret line. This cut went without a hitch.

Now the body. This one was difficult. Not only do I need to get the body aligned but the resultant mortise needs to fit snug. Made a couple of passes with the router and all looked good. Pulled it out and realized it wasn’t perfect. Missed a bit on the second router pass and, for some reason, didn’t go deep enough. Sigh. Ended up putting the body back into the jig. Recreating the exact alignments was quite the challenge. Made another pass. Success! The neck/body joint is perfect and the alignment of the neck centerline to the body centerline has never been more, well, aligned. This jig is awesome! Anyone interested can get plans from Robert O’Brien Guitars or LMI. I heavily modified the plans as well as created custom templates to work for soprano thru baritone ukuleles.

I’ll add a neck/body screw tomorrow. I’m spent. Time for a Mai-Tai.

I would say that the Mai Tai was well earned! Now that you have all of these wonderful jigs you need to crank up the marketing campaign so that you can get some more commissions. That is a lot of jigs if you only make one. I am again in awe of the precision that you achieve.