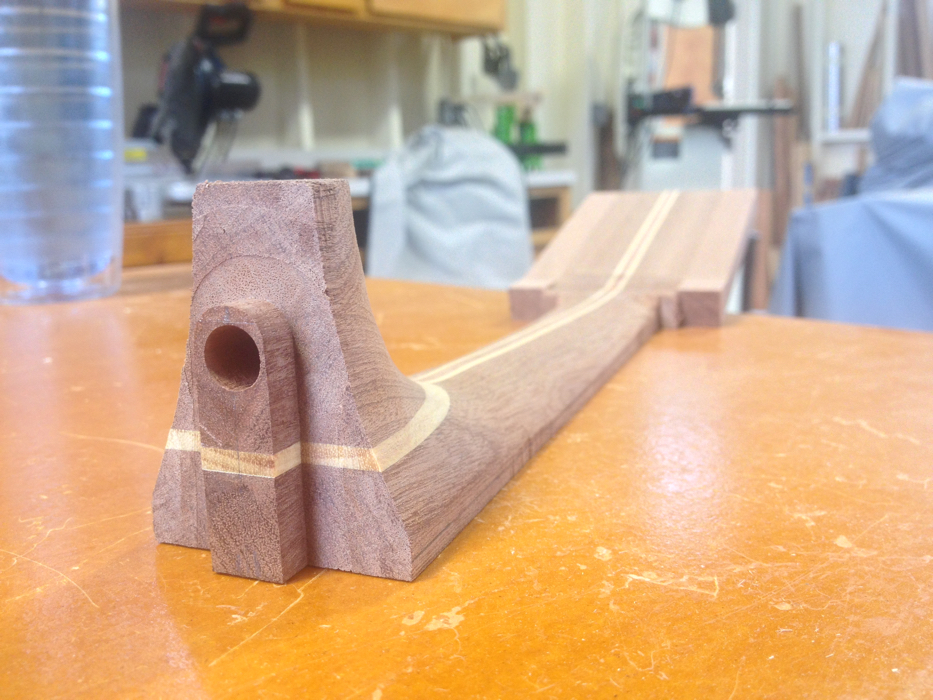

While it’s probably overkill, I use a furniture bolt and brass threaded insert nut to create a solid neck/body connection.

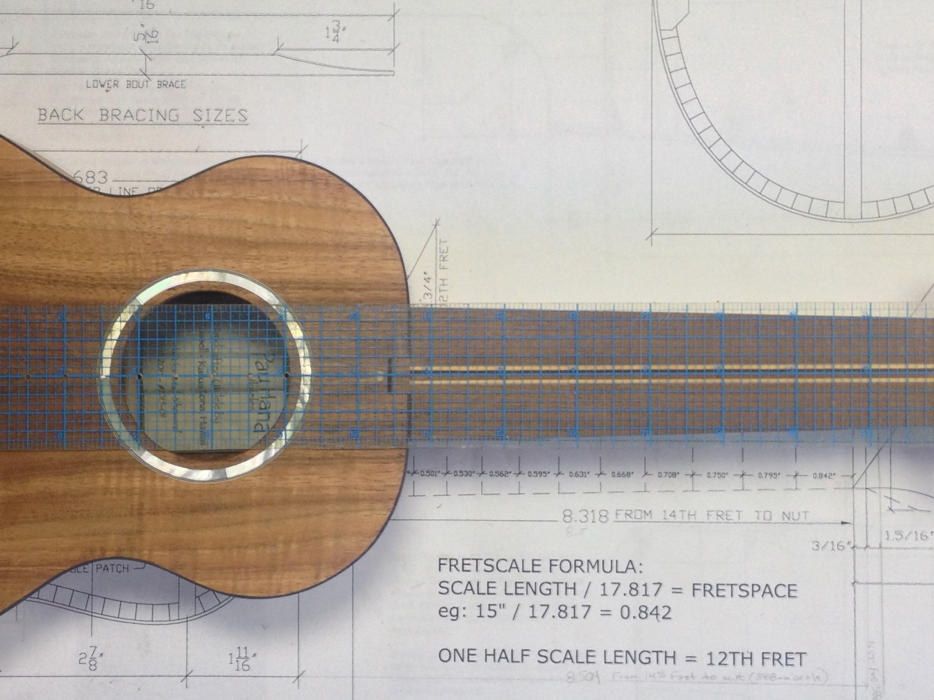

The tenon is about 1/2″ wide while the insert needs a 3/8″ hole. Nice tight tolerances. I created a simple jig to mount the neck vertically in the drill press using a carbon fiber rod in the neck (and a matching slot in the jig) to insure stability/rigidity. Using a 3/8″ Forstner bit and a light touch, the hole was made. Prior to inserting the nut, super glue was added all around the hole to improve the integrity of the hole sides. It must have worked as the sides did not split. The hole, insert, tenon and mortise all aligned perfectly. Most importantly, the geometry of the neck and body is excellent

Leave A Comment

You must be logged in to post a comment.