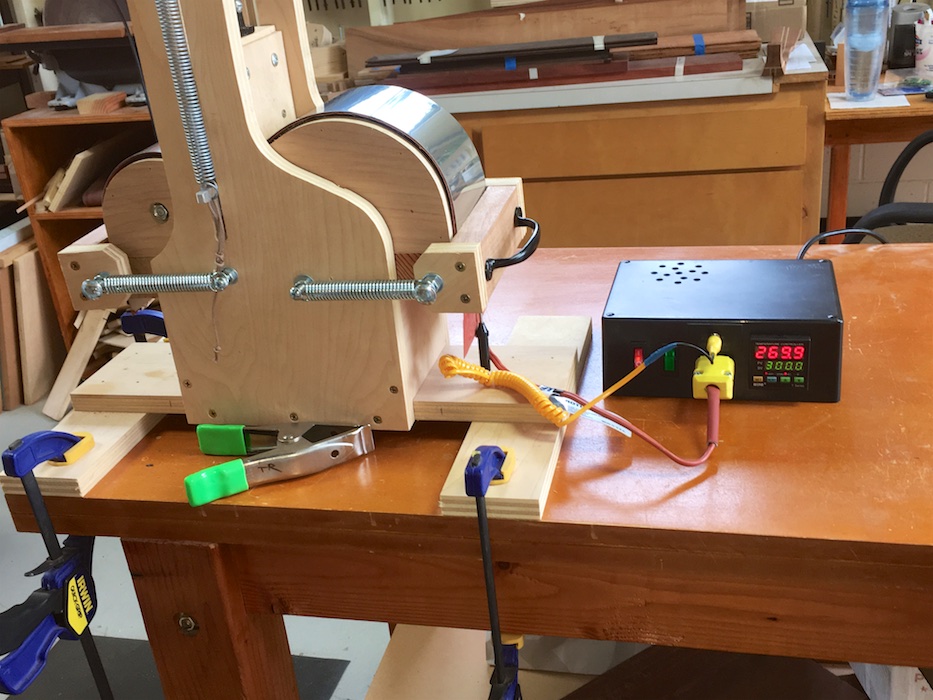

Got some quality time in a past couple of day. Got to try out my homemade Temperature Controller for bending sides. Created a sandwich of wetted koa sides wrapped in paper towels (to soak up oils) and wrapped again with aluminum foil. Then into the bender using a stainless steel slat, the side sandwich, the blanket and another slat. To avoid drying out the ends , I let the ends be loose until finishing the waist bend. Set the controller to 280 degrees to begin the bend. Worked flawlessly!. After bending the sides, I set the controller to 250 and let it set for 15 minutes. This helps “set the sides” to the new shape. Added the heel and end blocks, then sanded the front flat and the back to a 12 foot radius curve. Set all that aside.

I set the bracing and center strip on the back and, once the glue set up, shaped the braces. Next time I’ll pre-shape the bracing more than I did this time. Way too much sanding!

Finally prepped the kerfing prior to glueing up. I wanted to shave off some of the width to have about 7/16″, the standard Hana Lima ‘Ia product is 11/16″, too wide for an ukulele (IMHO). Created a nice little thickness sander using my spindle sander and a clamped board. Very nice! Make sure to feed against the spindle’s rotation!

Leave A Comment

You must be logged in to post a comment.