Finally back in the shop! Between having family over for the Holidays and then immediately getting the flu, it’s been a long time. First up, prepping the body for kerfing. Flatting the top is straight forward…leave the sides in the form and sand against a very flat surface. The bottom is trickier. Using a 15 foot radiused dish lined with sandpaper, I sanded the bottom of the sides to create a curved shape (you can sort of see the gentle curve in the picture with the green background). Quite a process as the sides are thin but the end blocks are wide. Once the back is glued on, that curve creates a pleasing shape and help reflect sound waves within the body hopefully creating a warmer & rounder tone.

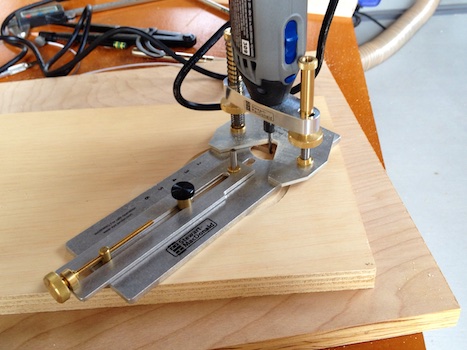

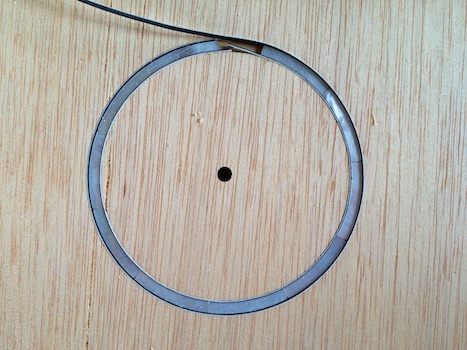

I also played around with my new precision router base from Stew-Mac. This tool has a very fine adjustment allowing me to create extremely accurate rosette channels. I plan on using white mother-of-pearl with some purfling on the outside edges. The pics don’t really reflect the final outcome as the heights of the MOP and purfling are different. One pic shows a thin white/black then MOP then a thick black/white/black strip. Another shows the MOP sandwiched between pieces of white/black purfling. Having black against the white MOP will accent the shell nicely. Stew-Mac tools, while expensive, sure feel great in the hands and work flawlessly. I can’t believe I used a circle-cutter on my drill press in the past.

Glad to see that you are back in the shop Kona Tom. Great progress, I really like the MOP work on the rosette. Not sure that I understand how you are using the 15′ tool to put the radius on the back. Do you use it like a giant sanding block? Mahalo!

Pictures don’t really show what’s going on. Yes, that black square is, in essence, a sanding block. The black sanding surface is actually dished out with an arc whose curvature is identical to an arc of a circle with a radius of 15 feet. Depending on the instrument type and desired shape, that arc might be based off a radius of 12′, 15′, 25′ or 30′. Most ukulele makers use a 15′ radius arc but certainly not a rule. Anyway, while the sides’ edges pointing towards the front of the uke are flat, the backside has that curve. You can see in the photo that I’ve taken the sides and shaped them on that sanding block in a circular motion. Takes some time to do by hand. A jig I’d like to make is taking that sanding block after making it round, mount it on my drill press and use the drill press to spin the block with some type of rubber wheel mounted in the chuck. Sort of like gears in a clock without the teeth.