Creating the sides is (now!) a very straight forward proposition. First, I dimension lumber to size and final thickness. Then they are tapered from roughly the mid-point to the head and heel (top and bottom) along the back-side edge. This is done to ultimately provide a slightly arched back which helps the overall sound and sound projection.

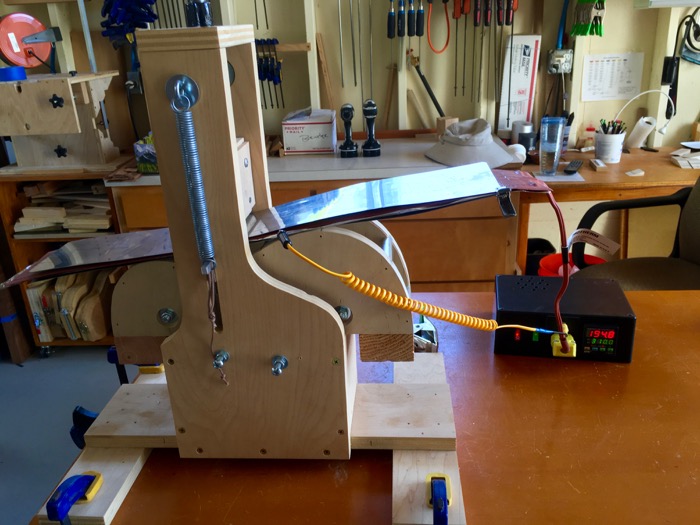

The prepared sides are dampened then wrapped in parchment paper and aluminum foil. This “sandwich” is placed in the bender surrounded by steel slats and a heating blanket. The homemade temperature controller heats it all up to about 300 degrees to get the steam going and the wood pliable.

After bending, the sides are placed into forms to maintain shape. Finally, blocks of mahogany are glued to the head and heel for both connecting the sides together and provide overall stability for the fretboard.

Leave A Comment

You must be logged in to post a comment.